Casing Pipes and Connectors: Engineered for Reliability and Performance in the Oil and Gas Industry

At United Drilling Tools Ltd. (UDT), we specialize in designing and manufacturing Large OD casing pipes with high performance connectors that meet the most demanding requirements of the oil and gas industry. Specializing in Fast make-up, Weight set, Metal to Metal seal and Flush OD/ID connectors, UDT delivers solutions that streamline drilling operations, minimize rig time, and ensure optimal performance in the harshest environments. With over 30 years of expertise, our products are trusted globally for their quality, durability, and superior performance. Whether you are working on land, offshore platforms, or Deepwater operations, UDT’s casing pipes and connectors provide the strength and reliability you need for successful oil and gas exploration.

Key Features of UDT Casing Pipes and Connectors

- Top-of-the-Line Design

Our casing pipes and connectors are engineered to meet the rigorous demands of the oil and gas industry. UDT excels in the design and manufacturing of fast make-up connectors, offering both threaded and weight set designs. Our connectors are engineered for easy installation, faster make-up times, and superior sealing capabilities, making them the ideal choice for a wide range of drilling applications. - Integrated Connector System

UDT’s casing connectors ensure a seamless connection between casing pipes, promoting optimal alignment and a secure fitment. This system minimizes the risk of leakage and ensures long-term reliability. - Versatile Size Range

We offer casing pipes and connectors in a wide range of diameters—from 18.625” to 40”—with varying wall thicknesses, providing the flexibility to meet diverse project specifications. - Efficiency-Driven Solutions

The threaded connectors are designed to simplify the process of making up large diameter casing, saving valuable rig time. This efficiency helps accelerate operations, increasing productivity and reducing costs for oil and gas companies. - Certified for Quality

Our products are manufactured in compliance with industry standards, offering Product Specification Levels (PSL-1 & PSL-2), ensuring top-notch quality and reliability for all applications. Our connectors are made to meet the most stringent industry specifications, with precise machining carried out on state-of-the-art CNC machines to ensure accuracy and performance.

Applications of UDT Casing Pipes and Connectors

UDT’s casing pipes and connectors are ideal for a variety of application programs in the oil and gas industry, including:

- Land-based Operations

- Offshore Platforms

- Jack-Up Rigs

- Floating Units

- Deepwater Exploration

Whether you’re drilling on land or in deepwater fields, our casing systems offer the durability and strength required for both shallow and ultra-deepwater drilling.

Types of UDT Connectors

UDT offers a wide range of connectors tailored to meet the specific needs of different drilling operations. Our high-strength, reliable connectors ensure smooth operations and long-term performance.

- UDT Leopard: A high-strength connector designed for quick fitment and superior high-pressure sealing, ensuring reliability in critical applications.

- UDT Swift: Features both metal-to-metal and elastomeric O-ring seals, offering enhanced sealing performance for a wide range of drilling conditions.

- UDT Lynx: A robust weight set connector designed for heavy-duty applications, providing secure and reliable make-up in high-pressure environments.

- UDT Puma: A high-strength connector with flush OD/ID and dual sealing options, delivering exceptional performance in challenging operations.

General Features of UDT Connectors

- Self-Aligned Design: Our connectors are designed for ease of use and straightforward installation, reducing the potential for errors during assembly.

- Superior Strength: UDT connectors exhibit higher strength characteristics than the casing pipes themselves, providing robust connections that can withstand the toughest conditions.

- No Cross Threading: Our connectors are engineered to prevent cross threading, ensuring smooth and reliable installation without complications.

- Quick and Easy Stabbing: The design facilitates rapid connection, saving time and enhancing operational efficiency.

- Reusable: The reversible design ensures that connectors can be reused multiple times, improving long-term value and reducing costs.

- Visual Feedback: Clear visual indicators on the connector offer immediate feedback on the make-up status, allowing operators to monitor the installation process with confidence.

- Fatigue Preloaded: Built to handle cyclic loads, UDT connectors are fatigue preloaded to ensure reliable performance over the life of the project.

- High-Pressure Sealing: UDT connectors are designed with high-pressure sealing capabilities, maintaining integrity and preventing leaks under challenging drilling conditions.

- Corrosion Protection: To protect against corrosion and galling, UDT connectors are phosphate-coated, ensuring durability even in harsh environments.

- Industry Certifications: Our connectors are certified under ISO 13679:2019, CAL 1, demonstrating our commitment to meeting the highest quality standards in the industry.

| UDT LEOPARD | UDT SWIFT |

| UDT LYNX | UDT PUMA |

Manufacturing Capabilities of UDT Connectors

At UDT, we pride ourselves on precision and excellence in manufacturing. Our advanced machining capabilities ensure that we can deliver high-quality connectors with tight tolerances and superior performance.

- Precision Machining: UDT utilizes CNC horizontal and vertical lathes with an accuracy of up to 1/1000 of an inch, ensuring the precision and quality of every connector.

Large Component Capability: We can machine large components up to 42 inches in diameter, maintaining tight tolerances for each piece.

Advanced Fabrication Process for Connector to Casing Joints

Our manufacturing process ensures precision and quality in every product. We utilize advanced technologies and follow stringent industry standards to produce casing joints that guarantee superior performance.

- Laser Alignment for Precision

We employ advanced laser alignment systems to ensure perfect axial alignment and connector parallelism, in accordance with API RP 5C6 standards. - State-of-the-Art Welding Equipment

UDT uses top-tier welding equipment from leading manufacturers like Esab, Lincoln, and Ador. Our team uses various welding methods, including SAW, TIG, and MIG, ensuring strong, high-quality welds. - Compliance with Industry Standards

Our fabrication processes adhere to pre-qualified WPS (Welding Procedure Specification) and PQR (Procedure Qualification Record) in compliance with API 1104 and API RP 5C6, ensuring quality and consistency.

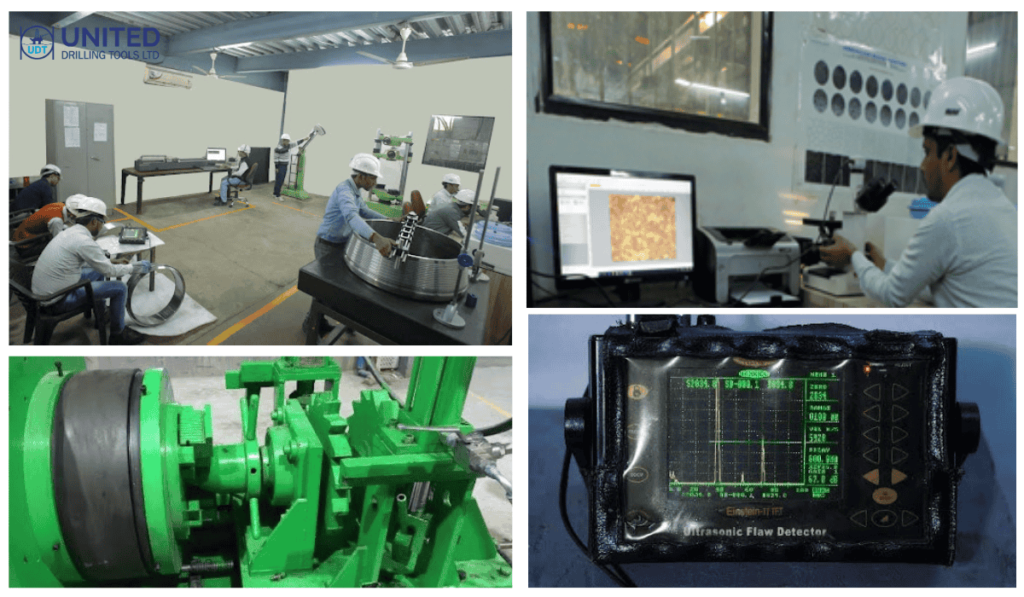

Quality Assurance and Testing of UDT Connectors

UDT is committed to providing only the highest-quality products, and our quality assurance program ensures that every connector meets the most demanding specifications.

- Established QA Lab: Our in-house quality assurance lab conducts both destructive and non-destructive testing to verify the performance of each connector.

- Destructive Testing: Tensile, impact, and hardness tests are conducted to verify the physical properties of connectors.

- Non-Destructive Testing: Our connectors undergo ultrasonic testing and metallographic evaluation to ensure they meet industry standards.

- Dimensional Accuracy: Each connector is inspected for dimensional accuracy using calibrated quality instruments to guarantee a precise fit.

- Fitment Testing: Every connector undergoes 100% fitment testing using advanced torque-tightening machines to ensure perfect installation.

Corrosion Protection: All connectors are phosphate-coated to prevent corrosion and enhance durability, even in harsh environments.

Rigorous Quality Inspection and Traceability of Casing pipe with connector joint

UDT is committed to maintaining the highest standards of quality in the manufacturing of casing pipes and connectors. To ensure the best performance, we implement a comprehensive quality inspection and traceability process.

- Manufacturing Quality Test Plan (QTP)

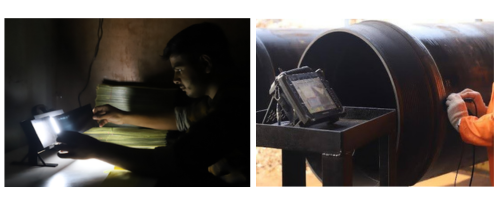

Our QTP is pre-approved by clients to ensure compliance with specific inspection criteria, giving you confidence in every product we deliver. - Advanced Inspection Methods

We utilize cutting-edge inspection techniques, including phased array and radiographic testing, to verify weld integrity and ensure that our products meet API Spec 1104 and API RP 5C6 standards. - 100% Material Traceability

Each casing joint is linked to a unique serial number, providing full traceability for the materials used. This ensures complete transparency and confidence in the quality of our products.

R&D and Advanced Testing of UDT Connectors

At UDT, we continually invest in research and development to improve our connectors and ensure they meet the latest industry standards.

- Experienced Design Team: Our team of engineers uses advanced finite element analysis (FEA) to optimize connector designs for performance and reliability.

- ISO Compliance: All of our designs comply with ISO 13679:2019, CAL 1 requirements, ensuring that our connectors meet the highest standards in the industry.

- Advanced Testing Facilities: Our testing facilities include machines for tension, compression, bending, and pressure testing to verify the capabilities of our connectors under real-world conditions.

Fast Turnaround for Timely Project Execution

At UDT, we understand the importance of quick delivery to keep your project on track. Our efficient inventory management system ensures that we can offer rapid turnaround times for casing pipes and connectors.

- Short Lead Times

By maintaining a ready inventory of connectors and raw materials, we can provide quick and efficient delivery, minimizing project delays. - Flexible Delivery Options

We offer flexible stocking, maintenance agreements, and expediting programs tailored to meet your project schedules.

After-Sales Service and Support

UDT believes in providing comprehensive after-sales service to ensure smooth installation and ongoing performance of our casing pipes and connectors.

- Installation Assistance

We offer free service engineer support for the initial installation of casing joints, ensuring a seamless process. - Experienced Engineers

Our team of engineers boasts over 10 years of offshore drilling experience, offering expert guidance and technical support. - Training and Technical Support

UDT provides training for rig technicians to ensure proper installation and maintenance of our casing pipes and connectors, enhancing the overall efficiency of your operations.

Sales Performance and Track Record

With a proven track record, UDT has sold over 300 km of large OD conductor casing with connectors and more than 85,000 multi-start fast make-up connectors. Our products are trusted by operators worldwide to deliver reliable, efficient, and cost-effective solutions.

Why Choose UDT Casing Pipes with Fast make up and weight set Connectors?

When it comes to reliable, high-performance Casing pipe and connectors, UDT offers the best in the business. With our commitment to quality, advanced manufacturing processes, and years of industry experience, we provide connectors that make your drilling operations safer, faster, and more efficient. With decades of experience, cutting-edge technology, and a focus on quality, UDT has earned a reputation as a trusted supplier of casing pipes and connectors to the global oil and gas industry. Our products deliver exceptional performance, reliability, and value, making them the ideal choice for your oilfield operations.

Contact UDT today for more information about our Casing pipe with Fast make-up, Weight set, Metal to Metal seal and Flush OD/ID connectors and discover how our solutions can enhance your drilling operations.