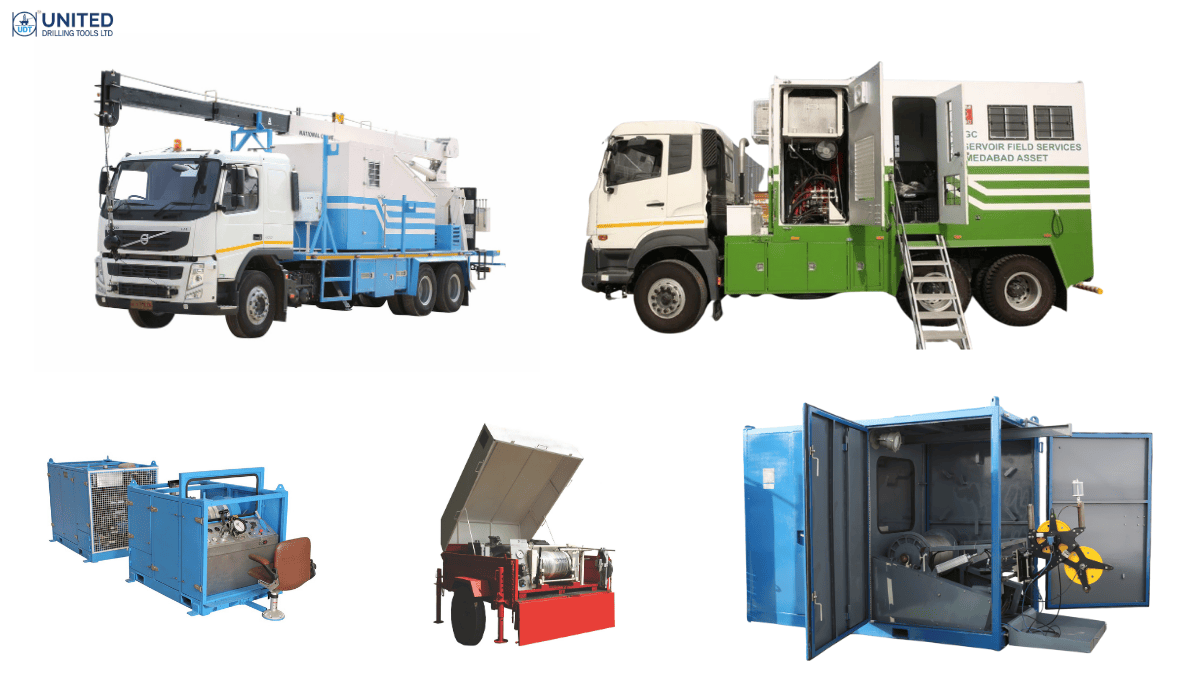

Comprehensive Guide to UDT Wireline Winches: Applications, Features, and Variants

Wireline winches are essential equipment used in the oil and gas industry for slickline operations in oil wells. These machines facilitate a wide range of operations such as tool deployment, pressure surveys, bailing debris, and maintenance. UDT Wireline Winches are renowned for their quality, safety features, and versatility. In this comprehensive guide, we will drive deep into the different types of UDT wireline winches, their applications, safety features, and more.

What is a UDT Wireline Winch?

A UDT Wireline Winch is a hydraulic-powered machine used primarily in oil well operations, specifically for slickline services. Slickline refers to a single-strand wire that is run into the wellbore to perform various tasks such as tool deployment, Slickline & Fishing operations, and pressure or temperature monitoring. The winch’s drum, which holds and releases the wire, is managed hydraulically, providing precision in deployment and retrieval.

UDT manufactures various types of wireline winches tailored for specific operational requirements. Their winches are renowned for their robust design, safety features, and ability to operate in challenging offshore and onshore environments.

Types of UDT Wireline Winches

UDT offers a wide variety of wireline winches, each designed for specific applications. Below are the major types:

1. UDT Slimsplit Winch

UDT Slimsplit Winch is a compact, hydraulic-powered winch designed for slickline operations in both onshore and offshore locations. This model is particularly suited for production tubing operations and reservoir monitoring.

- Configurations: The winch is available in single drum and double drum configurations, offering flexibility depending on the scale of operations.

- Hydraulic Control: It uses a closed-loop hydraulic system with a variable displacement pump and motor, ensuring high efficiency and reliability during operations.

- Drum Capacity: The winch drum can accommodate 20,000 ft to 25,000 ft of 0.092”, 0.108” & 0.125” slickline, catering to various well depths.

- Line speed and Pull capabilities: Maximum line speed at rim/surface – 2700 ft/min & Maximum line pull at core – 9000 lbs.

- Power Pack: 84 – 125 HP diesel engine driven hydraulic power pack.

- Data Monitoring: The winch is equipped with a digital data recorder that displays and records real-time depth, tension, and line speed. This allows for precise control during operations.

- Safety and Control: The winch is equipped with fail-safe braking systems and over-pull shutdown features. It also includes a measuring head for precise depth, tension, and speed measurements.

- Customization: Available with a range of options such as touch screen winchman panels, air-conditioned operator cabins, double drum units & frame as per DNV 2.7-1

2. UDT Flyline Winch

UDT Flyline Winch is designed for operations where mobility and flexibility are essential. These winches are skid-mounted and can be equipped with a diesel engine-driven hydraulic power pack for easy transport and setup.

- Applications: Ideal for offshore and onshore production and reservoir operations.

- Drum Capacity: The winch drum can accommodate 20,000 ft to 25,000 ft of 0.092”, 0.108” & 0.125” slickline, catering to various well depths.

- Line speed and Pull capabilities: Maximum line speed at rim/surface – 2700 ft/min & Maximum line pull at core – 9000 lbs.

- Power Pack: 84 – 125 HP diesel engine driven hydraulic power pack.

- Data Monitoring: The winch is equipped with a digital data recorder that displays and records real-time depth, tension, and line speed. This allows for precise control during operations.

- Safety and Control: The winch is equipped with fail-safe braking systems and over-pull shutdown features. It also includes a measuring head for precise depth, tension, and speed measurements.

- Customization: Available with a range of options such as touch screen winchman panels, air-conditioned operator cabins, double drum units & frame as per DNV 2.7-1.

3. UDT Truckline Winch

UDT Truckline Winch is truck-mounted, making it perfect for onshore operations. The winch is mounted on a 6×4 drive truck chassis, providing the mobility and power needed for a variety of slickline operations.

- Configurations: The winch is available in single drum and double drum configurations, offering flexibility depending on the scale of operations.

- Hydraulic Control: It uses a closed-loop hydraulic system with a variable displacement pump and motor, ensuring high efficiency and reliability during operations.

- Drum Capacity: The winch drum can accommodate 20,000 ft to 25,000 ft of 0.092”, 0.108” & 0.125” slickline, catering to various well depths.

- Line speed and Pull capabilities: Maximum line speed at rim/surface – 2700 ft/min & Maximum line pull at core – 9000 lbs.

- Power: The truck-mounted winch is powered by diesel engines rated from 200 HP to 420 HP in addition to onboard 84-125 HP diesel engine, ensuring it can handle demanding tasks in rig-safe zones.

- Safety and Control: The winch is equipped with fail-safe braking systems and over-pull shutdown features. It also includes a measuring head for precise depth, tension, and speed measurements.

- Operator Features: The unit comes with a well-designed operator cabin, ergonomic seating, and a communication system to maintain safety and efficiency.

- Data Monitoring: The winch is equipped with a digital data recorder that displays and records real-time depth, tension, and line speed. This allows for precise control during operations.

- Customization: Available with a range of options such as touch screen winchman panels, air-conditioned operator cabins &double drum units.

4. UDT Landline Winch

UDT Landline Winch is another truck-mounted wireline winch that is designed for slickline operations. This winch is equipped with advanced features that allow for increased operational flexibility.

- Configurations: The winch is available in single drum and double drum configurations, offering flexibility depending on the scale of operations.

- Hydraulic Control: It uses a closed-loop hydraulic system with a variable displacement pump and motor, ensuring high efficiency and reliability during operations.

- Power: The truck-mounted winch is powered by diesel engines rated from 280 HP to 420 HP, ensuring it can handle demanding tasks in rig-safe zones.

- Drum Capacity: The winch drum can accommodate 20,000 ft to 25,000 ft of 0.092”, 0.108” & 0.125” slickline, catering to various well depths.

- Line speed and Pull capabilities: Maximum line speed at rim/surface – 2700 ft/min & Maximum line pull at core – 9000 lbs.

- Swiveling Operator Cabin: One of the standout features of this winch is the swiveling operator cabin, which provides excellent visibility and ease of operation during well interventions.

- Crane Capacity: The winch features a 5-22 ton capacity telescopic boom crane, which can be used for tool handling and installation. The crane comes with an overload prevention system, ensuring safe operation.

5. UDT Scrapping Winch

UDT Scrapping Winch is a light-duty, skid/trailer-mounted winch, specifically designed for bailing, fluid level testing, paraffin cutting, and bottom tagging.

- Compact Design: This winch is lightweight and compact, making it perfect for operations that do not require the heavy-duty capabilities of other models.

- Power: The winch is powered by a 23 HP petrol engine, making it ideal for smaller operations where a high level of mobility is required.

- Line speed and line pull capabilities: Max line speed at rim – 350 m/min & Max line pull at core – 1800 lbs+.

- Applications: It is mainly used for onshore operations such as sand and debris bailing, paraffin cutting, and well intervention in low-pressure environments.

- Customization: Truck mounted PTO driven units can be supplied on customer request.

6. UDT Surveyline winch

UDT Surveyline Winch is a light-duty, skid mounted winch, specifically designed for bailing, fluid level testing, paraffin cutting, and bottom tagging.

- Compact Design: This winch is lightweight and compact, making it perfect for operations that do not require the heavy-duty capabilities of other models.

- Power: The winch is powered by a 25/30 HP Electric motor, making it ideal for smaller operations where a high level of mobility is required.

- Line speed and line pull capabilities: Max line speed at rim – 350 m/min & Max line pull at core – 1800 lbs+.

- Applications: It is mainly used for onshore operations such as sand and debris bailing, paraffin cutting, and well intervention in low-pressure environments.

- Customization: Power of electric motor and line speed/line pull can be customized.

7. UDT Telescopic Mastline unit

- UDT Telescopic Mastline are self-contained units designed for use on land wells with large amount of storage allows them to transport virtually all pressure control equipment’s like grease injection units, lubricator risers, BOP etc to the well.

- The height of the parallel boom from the platform at least 175 cm which is sufficient to keep Pressure control equipments, BOP etc

- Heavy duty truck chassis 6×4/8X4 drive of above 400 HP suitable for offroad hauling, construction sites, or areas with poor road conditions. 8×4 drive chassis are provided for Higher GVW-35000 KG which increases the Weight Carrying Capacity & Provides more Stability.

- Truck chassis features sleeper cabin with air conditioner for climate control.

- Heavy duty crane with maximum lifting capacity of 26 Tons and maximum lifting height upto 127 feet.

- Rear mount 360° stable unit, proportional / Sequence Synchronous boom extension with smooth glide wear pads with boom hoist cylinder

- Heavy duty efficient hydraulic system with automatic hydraulic oil cooler that supply hydraulic energy to the hoist, to the boom and outriggers, and to the swing (turn) circuit

- Weight distribution on front and rear axles will be so as to provide the maximum stability to the vehicle

- Crane has inbuilt alert systems both audio & visual ATB, LMI, automatic safe load indicator, boom angle indicator, boom length sensor indicator, safety latch for hook block, hoist limit switch system, safety harness for safe operations.

Key Applications of UDT Wireline Winches

UDT wireline winches are used in a variety of applications within the oil and gas industry. Below are some common uses:

- Tagging Total Depth (T.D.): The winch is used to deploy tools that help measure the total depth of the wellbore.

- Gauge Ring Runs: These winches facilitate the deployment of gauge rings, which are used to check the dimensions of the wellbore.

- Bailing Sand and Debris: UDT winches are used to remove sand, debris, and other foreign materials from the wellbore to ensure smooth operations.

- Gas Lift Valve Operations: These winches are used for setting and retrieving gas lift valves, which are crucial for the artificial lift process in oil production.

- Bottom Hole Pressure and Temperature Surveys: UDT wireline winches help deploy sensors to measure pressure and temperature at the bottom of the well.

- Spinner Surveys: Used to determine the orientation of the wellbore and assist in the placement of tools and equipment.

- Fishing Operations: Winches are crucial for fishing operations, where tools or equipment are retrieved from the wellbore.

- Paraffin Cutting and Chipping Ice/Salt: In colder environments, UDT winches are used for paraffin cutting and ice removal to maintain smooth wellbore operations.

Features and Benefits of UDT Wireline Winches

UDT wireline winches come with a range of advanced features designed to ensure safety, efficiency, and ease of operation. Below are some notable features:

1. Hydraulic System

- Closed-Loop Design: UDT wireline winches feature a closed-loop hydraulic system with a variable displacement hydraulic pump and motor, providing smooth operation with faster acceleration and high speeds.

- Dynamic Braking: The winches include a dynamic braking system that ensures safe operation by controlling the deceleration of the winch.

2. Safety Features

- Over Pull Shutdown: The winch has a built-in system to shut down winch rotation at preset over-pull values, protecting both the equipment and the wireline.

- Fail-Safe Braking: Most UDT wireline winches are equipped with a Pneumatic/hydraulic fail-safe band brake system for added safety during operations.

- Emergency Shutdown: An emergency stop button is included on the operator control panel for quick shutdown during unforeseen circumstances.

- BOP Controlling system: Wireline winches includes BOP Controlling panel for controlling the pressure control equipment’s line BOP, Stuffing box etc.

-

- Engine overspeed shutdown: Zone – 2 engines are equipped with Overspeed shutdown valves, which in turns shutoff the engine in case of overspeed.

3. Data Acquisition and Monitoring

- Digital Data Recorder: UDT wireline winches come with a digital data recorder/Touchscreen panel that tracks and records real-time depth, tension, and line speed.

- Measuring Head: The winches are equipped with a 2 or 3 wheel wrap around design measuring head that helps operators monitor the wireline’s depth, speed and tension accurately.

4. Customization

- Tailored Designs: UDT wireline winches can be customized to meet specific operational needs, whether it’s the winch dimension & weight, drum capacity, engine power, or hydraulic system type.

Manufacturing and Quality Assurance

UDT wireline winches are manufactured with high-quality materials and precision engineering. UDT’s manufacturing facilities are equipped with advanced tools, including lathes, milling machines, and welding equipment. The company also conducts thorough testing, including load testing and winch line speed testing, to ensure that each winch meets the highest standards of performance.

Third-Party Inspections: UDT offers third-party inspections from leading agencies such as ABS, DNV, and BV to ensure compliance with international standards and regulations.

After-Sales Service and Support

UDT provides comprehensive after-sales support to ensure the continuous operation of their wireline winches. Services include:

- Installation and Commissioning: UDT’s experienced service engineers handle the installation and commissioning of the equipment.

- User Training: On-site training is provided to ensure operators are well-versed in using the equipment safely and efficiently.

- Spare Parts: UDT offers spare parts for two years after commissioning at no cost, ensuring minimal downtime and operational continuity.

Sales Milestone:

UDT has sold more than 285 numbers of different types of Slickline winches throughout the globe.

Why Choose UDT Wireline Winches?

When it comes to slickline operations, reliability, safety, and performance are non-negotiable. UDT Wireline Winches are built to withstand the toughest conditions, ensuring smooth and efficient operations. With their versatile applications, cutting-edge safety features, and customizable design, UDT winches are a trusted choice for oil and gas companies worldwide.

Conclusion

UDT wireline winches are an essential tool in modern oilfield operations, providing the flexibility, safety, and precision needed for slickline operations. From the compact and versatile Slimsplit Winch to the rugged Truckline Winch and the specialized Scrapping Winch, UDT offers a range of solutions for both offshore and onshore applications. With their advanced safety features, customization options, and exceptional after-sales service, UDT wireline winches stand out as an industry leader in providing high-performance and reliable winching solutions.