UDT Gas Lift Equipment: Comprehensive Overview and Specifications

UDT is a recognized leader in the manufacturing and supply of high-quality gas lift equipment designed for the oil and gas industry. UDT’s extensive range of gas lift systems, including Side Pocket Mandrels, Conventional Gas Lift Mandrels, and various flow control devices (such as Gas Lift Valves, Dummy Valves, and Orifice Valves), cater to the varied needs of oil and gas production. All equipment’s are rigorously tested to ensure compliance with industry standards like API Spec 19G1 & API Spec 19G2, while offering customizable materials based on client specifications.

General Features of UDT Gas Lift Equipment:

- Proven Design: UDT Gas Lift equipment are designed for reliable, efficient operation in demanding production environments. These systems have been field-tested in various global locations, ensuring a high level of trust and performance.

- Valve Compatibility: UDT’s gas lift valves are offered in 1-inch or 1.5-inch sizes (25.4mm and 38.1mm, respectively), providing flexibility for a range of applications.

- Durable Materials: All equipment components are made from premium-grade materials, including SS316, AISI 4130, L-80/13Cr, and Monel alloys, ensuring durability and corrosion resistance.

Types of UDT Gas Lift Equipment:

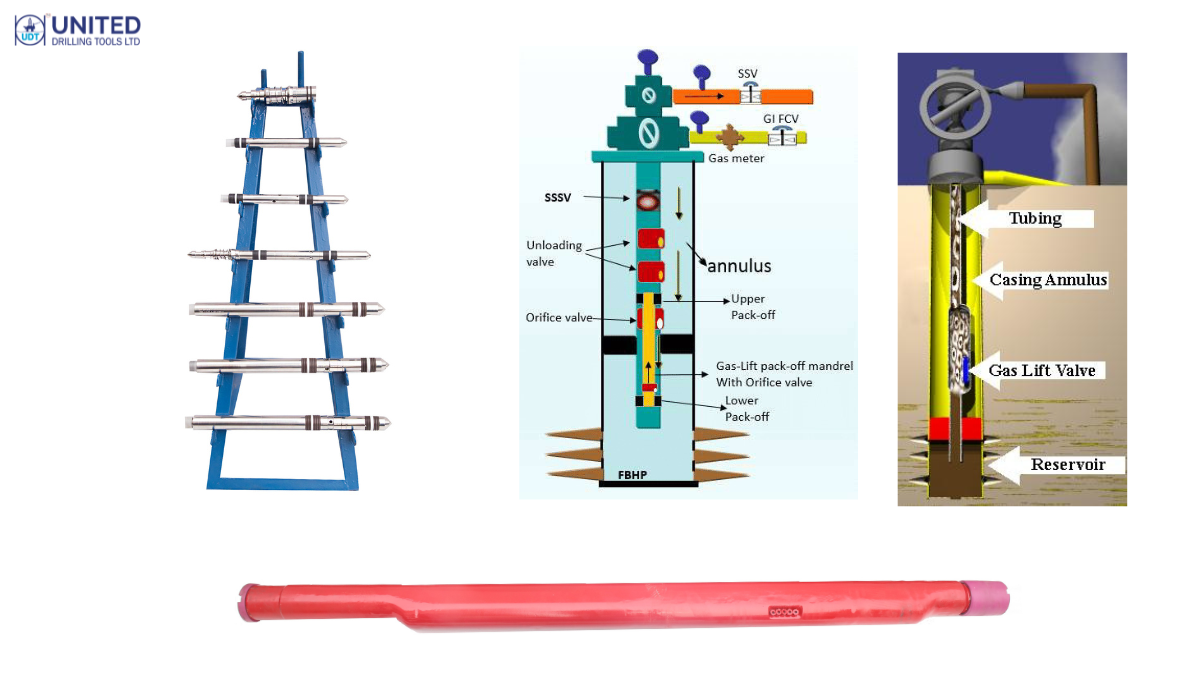

UDT Wireline Gas Lift Equipment:

- Side Pocket Mandrels:

- Functionality: These mandrels house gas lift valves to lift oil and gas when reservoir pressure is low. The unique side-pocket design ensures that the tubing can drift fully during well servicing.

- Compatibility: Suited for high-pressure, subsea, and deepwater applications.

- Design Features: Available with custom thread connections, including EU and premium threads & in oval and round body construction.

- Welding: Welding qualifies to ASME Section IX standard with quality control including ultrasonic testing & radiography testing.

- Material grade: Side pocket mandrels are manufactured from AISI 4130 as well as L-80/13Cr grade material for both the standard and sour service.

- Traceability: Full traceability through the manufacturing process and 100% dimensional inspection is performed.

- Wireline Retrievable Gas Lift Valve:

- Functionality: This valve uses nitrogen-charged Monel bellows to maintain a normally closed position, offering efficient gas lift operation.

- Key Features: Replaceable floating seat for easier maintenance and reverse flow check valve to prevent backflow.

- Port Sizes: These valves are manufactured in variety of port sizes to suit a wide range of gas injection volume & flow rates.

- Material Grade: Manufactured from a variety of premium grade materials to provide corrosion and erosion resistance for the intended application. Stainless steel or Monel options are typically utilized for the outer and main body components.

- Wireline Retrievable Orifice Valve:

- Purpose: These valves control the volume of injected gas into the wellbore, aiding in pressure regulation.

- Key Features: Incorporates backflow prevention and a tungsten carbide seat for wear resistance.

- Port Sizes: These valves are manufactured in variety of port sizes to suit a wide range of gas injection volume & flow rates.

- Material Grade: Manufactured from a variety of premium grade materials to provide corrosion and erosion resistance for the intended application. Stainless steel or Monel options are typically utilized for the outer and main body components.

- Wireline Retrievable Dummy Valve:

- Purpose: Dummy valves are used to block communication between the tubing and casing during certain stages of the gas lift process, enabling greater flexibility in operations.

- Key Features: Eliminates communication blockage and can be retained during new installations until gas lift valves are required.

- Material Grade: Manufactured from a variety of premium grade materials to provide corrosion and erosion resistance for the intended application. Stainless steel or Monel options are typically utilized for the outer and main body components.

- Latches, Running Tools, Pulling Tools, and Kick-Over Tools:

- UDT offers a variety of latches for locking valves in place, running tools for easy valve installation, pulling tools for valve retrieval, and kick-over tools designed for operations in highly deviated wells.

UDT Conventional Gas Lift Equipment:

- Conventional Mandrels:

- Purpose: These mandrels hold tubing-retrievable gas lift valves and orifice valves, offering flexibility in various well configurations.

- Key Features: Equipped with external lugs for easy retrieval and installation, plus tool guards for added protection.

- Welding: Welding of lug with tubing pupjoint qualifies to ASME Section IX standard with quality control including liquid penetrant testing & ultrasonic testing.

- Inspection: QA inspection includes weld visual inspection, Hardness testing, internal and external pressure testing and drift testing.

- Material grade: These mandrels are available in a variety of thread connections like EU and /or premium thread configurations as required by customers.

- Tubing Retrievable Gas Lift Valve:

- Functionality: These valves offer efficient gas lifting, even in conditions where reservoir pressure is insufficient.

- Key Features: Includes a guided valve stem for precise alignment and a mechanical stop for stability.

- Material grade: Manufactured from a variety of premium grade materials to provide corrosion and erosion resistance for the intended application. Stainless steel or Monel options are typically utilized for the outer and main body components.

- Gas charging: These valves can be charged with nitrogen gas from 400-1800 psi.

- Inspection and testing as per the stringent requirements of erstwhile API 11V1 & API 19G2 Specifications.

- Tubing Retrievable Reverse Flow Check Valve:

- Purpose: Used to prevent backflow, which can damage the casing and shorten the lifespan of gas lift valves.

- Key Features: Features dual seals and a robust stainless steel dart for added durability.

Applications of UDT Gas Lift Equipment:

- Enhanced Production: Gas lift systems are essential for artificially lifting oil and gas from wells that cannot naturally flow, improving overall production.

- Rate Increase: By introducing gas to the wellbore, the equipment increases production rates, especially in wells that have declining pressure over time.

- Deviated Wells: UDT’s equipment is highly suitable for deviated or horizontal wellbores, helping to maximize production from complex well designs.

- Solid Removal: Gas lift systems also facilitate the removal of solids by backflowing, addressing issues like scale or sand in the wellbore.

- Problematic Wells: Gas lift equipment is ideal for dealing with sand and scale issues in wells that require a non-invasive solution to maintain flow.

-

Manufacturing Capabilities:

- Precision Machining: UDT utilizes state-of-the-art CNC horizontal lathes for precision machining with an accuracy of 1/1000 inch, ensuring the highest level of quality.

- Advanced Brazing Facility: The brazing of components, such as ball and bellow brazing, is performed according to strict API specifications.

-

Quality Assurance and Testing:

- Comprehensive QA Lab: UDT maintains a comprehensive quality assurance lab that performs both destructive and non-destructive testing.

- Destructive Testing: Tests include tensile, impact, and hardness testing to verify the physical properties of materials used in the manufacturing process.

- Non-Destructive Testing: Ultrasonic testing is performed by qualified personnel to ensure structural integrity and eliminate any potential defects in the material.

- Dimensional Accuracy: All equipment undergoes rigorous dimensional inspection using calibrated quality instruments to ensure they meet all design specifications.

- Brazing Standards: UDT’s brazing processes comply with ASME Section IX standards, ensuring quality and consistency.

After-Sales Service:

- Installation Support: UDT provides free-of-charge service engineer support for initial installation and ensures that installation is smooth and efficient.

- Experienced Engineers: Access to highly experienced engineers with over 10 years of offshore experience to ensure optimal installation and operation of gas lift equipment.

- Training for Technicians: UDT engineers assist rig technicians by providing training on the proper installation of gas lift equipment, ensuring proper understanding of the systems.

Sales Milestone:

With over 22,000 units of gas lift equipment sold globally, UDT has proven itself as a reliable supplier to the oil and gas industry.

Conclusion:

UDT’s Gas Lift Equipment is an indispensable tool in the oil and gas industry, offering reliable, efficient, and versatile solutions for various production challenges. From Conventional to Wireline retrievable equipment, UDT provides a full range of components that can be tailored to meet the unique needs of customers in different operational environments. The company’s commitment to quality, innovation, and after-sales service ensures that clients receive the highest level of support throughout the life of the equipment.